CONTACT US!

We have a Metallographic and Spectrometry Laboratory, Quicklab, Temperature Control and Traceability System in its Production

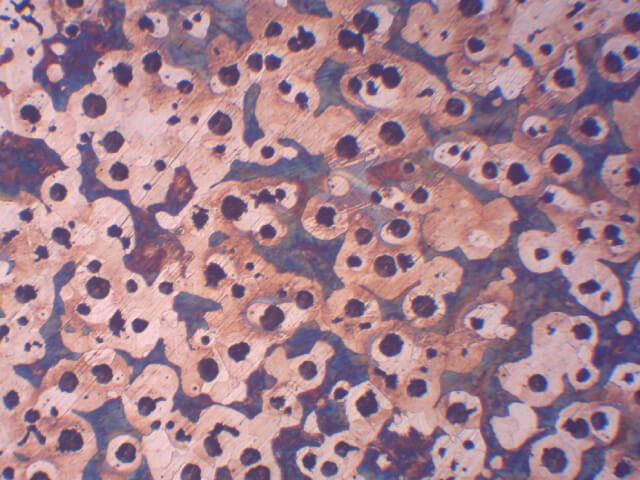

ASTM A536 standards under grades 60-40-18, 80-55-06 and 120-90-02

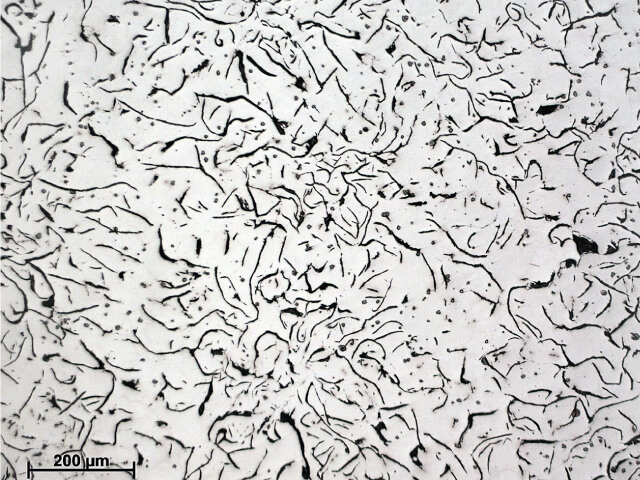

Manufactured under ASTM A48 standards under classes 20, 30, 40, 60

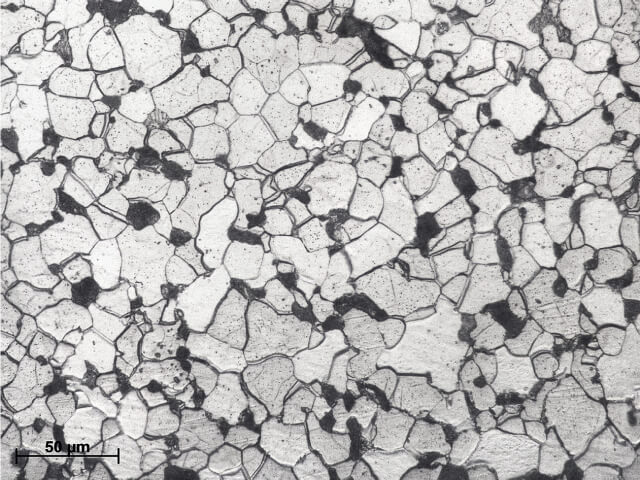

This material is manufactured under AISI-SAE 1020, 1030, 1045, 4140 and 4340 standards.

The induction furnace is environmental friendly unlike other smelting furnaces

It allows the control of the different alloys supplied to the material, avoiding volatilization and supply of impurities, guaranteeing its quality.

Resin molding allows obtaining best finishes superficial comparison of traditional sand while maintaining the geometry of the piece, reducing mold manipulation and accelerating production times.

The quick lab is a measuring instrument that allows the analysis of carbon and silicon in molten material, which are important for nodular and gray irons.

The immersion pyrometer allows you to control the temperature of the molten material to avoid defects in the material.

The spectrometer allow to analyze different elements within a sample, such as the carbon, silicon, manganese, chromium, phosphorus, copper, aluminum and others.

The microscope is used to determine the internal structure of the different alloy materials that are manufactured and whether they meet the requirements.

Dir: Km 13 Vía Mosquera – La Mesa, Bojacá / Colombia

Dir Oficina: Av Troncal Occidente # 1 - 59 Centro Logístico Portal Occidente